:

I think that any technique will take some skill to execute properly; although for some people "luck" seems to substitute very well for "skill".

You might want to use water-based acrylic enamel such as that made by Tamiya or Pactra. Assuming that your base paint is oil-based enamel or acetone-thinned lacquer, the water-based enamel can be removed with a swipe of a denatured alcohol-dipped rag if you mess up, without damaging the base paint. Wally Mart also sells a lower-grade, but perfectly serviceable, acrylic paint in their craft department which would also likely work fine.

Once you get the "appointments" painted just as you want them, you can seal the whole shebang with a light overcoat of gloss lacquer to provide a little more durability, if the radio is going to be handled much.

:

:I think that any technique will take some skill to execute properly; although for some people "luck" seems to substitute very well for "skill".

:

:You might want to use water-based acrylic enamel such as that made by Tamiya or Pactra. Assuming that your base paint is oil-based enamel or acetone-thinned lacquer, the water-based enamel can be removed with a swipe of a denatured alcohol-dipped rag if you mess up, without damaging the base paint. Wally Mart also sells a lower-grade, but perfectly serviceable, acrylic paint in their craft department which would also likely work fine.

:

:Once you get the "appointments" painted just as you want them, you can seal the whole shebang with a light overcoat of gloss lacquer to provide a little more durability, if the radio is going to be handled much.

:

Hi Again, well after trying many different methods I had to resort to a fresh large Black Sharpie and it worked GREAT!! Now a couple real light coats of clear gloss to set the ink so it won't run I should be good to go and able to put a couple heavy coats of clear gloss and buff it out. The paint was just to hard to handle maybe it's the bifocal glasses. LOL Best 2 U all, George T

A little late but these ideas work. Use a pencil erasure. Dip it into paint and dab it on lettering. Another idea, rollers are available to transfer ink. Transfer paint from one of these rollers to lettering/numbering. Painting this way won't give an uneven edge.

Norm

::The foam brush is about as good an idea as any. Another technique is rubber-sheet transfer- you coat the rubber sheet with a thin layer of paint, then immediately press it onto the surface features that you want painted. The thin sheets sold as "grip enhancers" for removing stuck jar lids work well for this. Imperfections can be touched up with a small brush.

::

::I think that any technique will take some skill to execute properly; although for some people "luck" seems to substitute very well for "skill".

::

::You might want to use water-based acrylic enamel such as that made by Tamiya or Pactra. Assuming that your base paint is oil-based enamel or acetone-thinned lacquer, the water-based enamel can be removed with a swipe of a denatured alcohol-dipped rag if you mess up, without damaging the base paint. Wally Mart also sells a lower-grade, but perfectly serviceable, acrylic paint in their craft department which would also likely work fine.

::

::Once you get the "appointments" painted just as you want them, you can seal the whole shebang with a light overcoat of gloss lacquer to provide a little more durability, if the radio is going to be handled much.

::

:Hi Again, well after trying many different methods I had to resort to a fresh large Black Sharpie and it worked GREAT!! Now a couple real light coats of clear gloss to set the ink so it won't run I should be good to go and able to put a couple heavy coats of clear gloss and buff it out. The paint was just to hard to handle maybe it's the bifocal glasses. LOL Best 2 U all, George T

:

|

:George

:

: A little late but these ideas work. Use a pencil erasure. Dip it into paint and dab it on lettering. Another idea, rollers are available to transfer ink. Transfer paint from one of these rollers to lettering/numbering. Painting this way won't give an uneven edge.

:

:Norm

:

:::The foam brush is about as good an idea as any. Another technique is rubber-sheet transfer- you coat the rubber sheet with a thin layer of paint, then immediately press it onto the surface features that you want painted. The thin sheets sold as "grip enhancers" for removing stuck jar lids work well for this. Imperfections can be touched up with a small brush.

:::

:::I think that any technique will take some skill to execute properly; although for some people "luck" seems to substitute very well for "skill".

:::

:::You might want to use water-based acrylic enamel such as that made by Tamiya or Pactra. Assuming that your base paint is oil-based enamel or acetone-thinned lacquer, the water-based enamel can be removed with a swipe of a denatured alcohol-dipped rag if you mess up, without damaging the base paint. Wally Mart also sells a lower-grade, but perfectly serviceable, acrylic paint in their craft department which would also likely work fine.

:::

:::Once you get the "appointments" painted just as you want them, you can seal the whole shebang with a light overcoat of gloss lacquer to provide a little more durability, if the radio is going to be handled much.

:::

::Hi Again, well after trying many different methods I had to resort to a fresh large Black Sharpie and it worked GREAT!! Now a couple real light coats of clear gloss to set the ink so it won't run I should be good to go and able to put a couple heavy coats of clear gloss and buff it out. The paint was just to hard to handle maybe it's the bifocal glasses. LOL Best 2 U all, George T

::

:

:

:

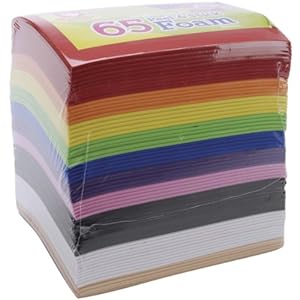

: : : : : : :  : : : : : : : :Sir . . . George Teeeeeeeeeeeeeeeeee : : : : : : : : :Late ADDENDA . . . .Internet went down last nite . . . but this is a possible alternative for next time. : : : : : : : : : : : : : : : : : :On that unit of yours, looks like you only have to highlight the Brand name lettering and the dialscale numbers. : : :I usually use two possible procedures for the paint topping of molded raised lettering. : : :A common FINE sable artists brush and the use of 50% thinned Testors model "DOPE". : : :Or I use a very fine polycellular foam which I have saved from products being packed within or around. : : :The grey foam brushes of Homeless Depots units have too large of open foam cells for me. : : :If not having some of that foam at hand, check HOBBY LOBBY in the crafts section for their sheets of it as: : : :  : : :It looks like different sheets of colored construction paper, but the foam is only ~1/8 in thick, they have it as single sheets, and white is the preferred color, to show up that paint put upon it. : : :If my job to do, I would be using a 2 inch or so length of wooden dowel and of a diameter slightly larger than a letters diameter. : : :Then cut out a foam circle to go on the end of the dowel . . . or do BOTH ends . . . using rubber cement or contact cement. : : :Then get rid of the outer side if the foam tips by doing a 45 degree taper with one of Mamma Cass's emery boards. : : :My choice for this unit would be Rub N' Buff in gold. : : :If you have ever done any printing, one puts a blob of printers ink on a sheet of glass ad then uses a roller brayer to get a universal even coating all over that sheet, and then the print/type is pressed onto it to obtain an even ink coat to then be pressed onto the paper to be printed upon. : : :In this particular case get an uniform coating of Rub N' buff on a scrap square of that foam materiel, press your "foam dauber" into the Rub N' Buff coated foam square with a press and ROTATE action. : : :Then you apply with a ROTATING action - slightly touch -and - lift off, while continually maintaining rotation. : : :Practice makes perfect and maintains uniformity . . . . while your left hand is griping a goof pad. : : :Its made from 2 "blue" paper shop towels, soaked in spirits paint thinner and squeezed out, to a just moist state, then the two are made into one ball to go into yet a 3rd dry blue towel, to make a round cleaning dauber, then it is pressed just enough to let the inner ball weep a trace of thinner into the outer towel. : : :Now if there is a bo-boo a swipe lets you repeat your coating. : : :Run 4 side strips of BLUE masking tape around your letters and mist coat on some Crystal Clear for a protective overcoat. : : : : : : : :73's de Edd : : : : : : : A fact . . . both Republicans and Democrats share one thing in common - our tax dollars. : : :Now . . . in order to close the budget deficit . . . we need to tax 4 out of every 3 Americans : : : : : : :  : |

:

:

:

:

:

:

::George

::

:: A little late but these ideas work. Use a pencil erasure. Dip it into paint and dab it on lettering. Another idea, rollers are available to transfer ink. Transfer paint from one of these rollers to lettering/numbering. Painting this way won't give an uneven edge.

::

::Norm

::

::::The foam brush is about as good an idea as any. Another technique is rubber-sheet transfer- you coat the rubber sheet with a thin layer of paint, then immediately press it onto the surface features that you want painted. The thin sheets sold as "grip enhancers" for removing stuck jar lids work well for this. Imperfections can be touched up with a small brush.

::::

::::I think that any technique will take some skill to execute properly; although for some people "luck" seems to substitute very well for "skill".

::::

::::You might want to use water-based acrylic enamel such as that made by Tamiya or Pactra. Assuming that your base paint is oil-based enamel or acetone-thinned lacquer, the water-based enamel can be removed with a swipe of a denatured alcohol-dipped rag if you mess up, without damaging the base paint. Wally Mart also sells a lower-grade, but perfectly serviceable, acrylic paint in their craft department which would also likely work fine.

::::

::::Once you get the "appointments" painted just as you want them, you can seal the whole shebang with a light overcoat of gloss lacquer to provide a little more durability, if the radio is going to be handled much.

::::

:::Hi Again, well after trying many different methods I had to resort to a fresh large Black Sharpie and it worked GREAT!! Now a couple real light coats of clear gloss to set the ink so it won't run I should be good to go and able to put a couple heavy coats of clear gloss and buff it out. The paint was just to hard to handle maybe it's the bifocal glasses. LOL Best 2 U all, George T

:::

::

::

:

:Kinda wish I would have waited a bit on this you guys have some great ideas. But as long as the ink doesn't run with the light coat of clear it should look really good. Might even post a picture of it. The customer wanted this color sceem I think her Grandfather painted it these colors shortly after he droped it and broke several pieces off of the cabinet. Me personally I would have gone with Ivory and gold. That is what it was originaly. Was able to make all of the repairs and you could never ID them, it really went well. I'm gona save this thread for future reference. Thanks Again, George T