Any insight appreciated.

img>

:Any insight appreciated.

= = = = = = = = = = = = = = = = = = = = = = = = = =

You first need to figure out what exactly is wrong with the pot. It either has an open in the resistance wire or the wiper is losing electrical contact with the wire due to oxidation or mechanical damage. Ohm the pot ends to determine the exact problem. If you have continuity end to end, try to clean the wiper face with 1000-grit wetordry sandpaper and then run the same paper gently over the winding contact face, then check for restored contact with an ohmmeter while you run the wiper end to end.

In the case of a wire break, the resistance wire cannot be soldered to repair a break (the wire alloy won't accept solder). However, it can be bridged with a small-diameter hollow brass tube crimped onto the two broken ends. You would have to remove the pot, locate the break, and unwind a couple of turns on each side to get enough wire length to attempt this "repair" (it is more of a kluge than a repair). This should restore most of the pot's range but it will have a dead spot at the repair- this may be OK, or it may not. If it isn't, reverse the end wires and you should be OK (although the pot adjustment-effect direction will be "backward" from normal).

Another possibility would be to remove the pot altogether and temporarily wire in a "stunt double" pot with similar electrical characteristics, then cal the meter. After cal, you can measure the pot resistance on both sides of the wiper and purchase two precision fixed resistors to replace the temp pot. This would make cal more labor-intensive but chances are you won't need to touch this setting that often, anyway.

Having said all that, it should be no big deal to find a suitable new mini-wirewound linear pot from a vendor such as Mouser. You probably have quite a bit of leeway in end-to-end pot resistance if you can't find an exact 3K replacement: higher resistance= less adjustment resolution; lower resistance= less adjustment range. The latter can be fixed with a padder resistor on one end or the other to "center" the pot.

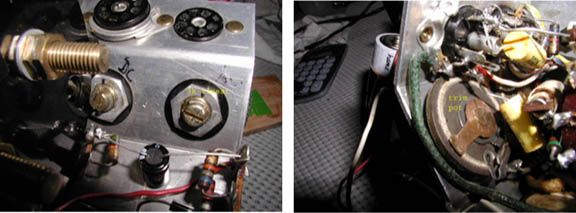

:My VTVM has a problem with the AC calibration pot. This is for a NRI model 11 and there seems to be no info on this model so I am without schematic or parts list. The functions of the meter work well after a rebuild except the AC needs some calibration. So yesterday I attempted a recalibration and after about 550 ohms of trimmer adjustment the meter goes dead on the AC function. After deoxit the pot performed no better. This pot is occupying a small space so I would like to repair or replace. It is a 11/8” diameter, 3k linear with a rim of wire wound indented and the wiper rides this. The thing is the ww seems to be covered with a flocking fabric and where it is worn off the wiper shorts out. Never seen anything like it. Made by clarostat. So the question is, anybody ever repair one? As you can see in the pic, the space is tight and there isn’t room to install a regular body pot cause it would be getting into tube socket terminals.

:Any insight appreciated.

:

:

:img>

:

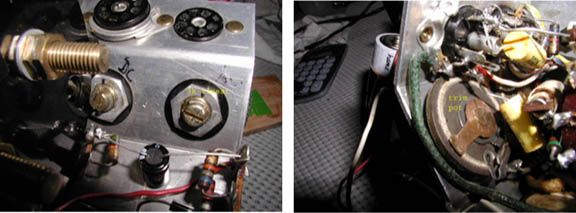

Based on feedback, I pulled this pot out and checked continuity end to end. No good. There is a definite open/short and there is not enough resistance reversing the end wires as there is more resistance value with original connections. It is strange but even under magnified light I can not make out any certain break area, but do see multiple, very small frayed wires at inside edge of wire winding. This ww seems like litz wire that was compressed into wafer slot and then the cloth was shaved off the top.( Possible? Don’t know.) So I slowly and by hand moved the wiper to maximum available resistance of 1759 ohms and that is very close to what I need to bring AC into acceptable accuracy. The ability to clean the wiper face or cover it with heat sink is a no go as the wiper is very tight against winding. The snap ring holding the wiper in is a thick bear so I though better off leaving alone for now. So, it is reinstalled and I will be keeping my eye out for backup replacement in case accuracy worsens.